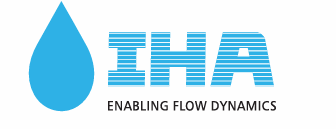

STARBLAZE 34L01 FIRE BARRIER COATING SYSTEM

StarBlaze 34L01 is a four component Fire Barrier System consists of very high -density fire & heat resistant mineral wool boards StarBlaze 34L04, coated with water-resistant StarBlaze 34K01intumescent coating, affixed with 34L03 Self expanding fire resistant sealant, which transforms into a hard ceramic during a fire to prevent the passage of fire and smoke and the transfer of heat. Specifically designed for sealing around cable & service penetrations in walls and below panels. Specifically designed for sealing around cable & service penetrations in walls and below panels.

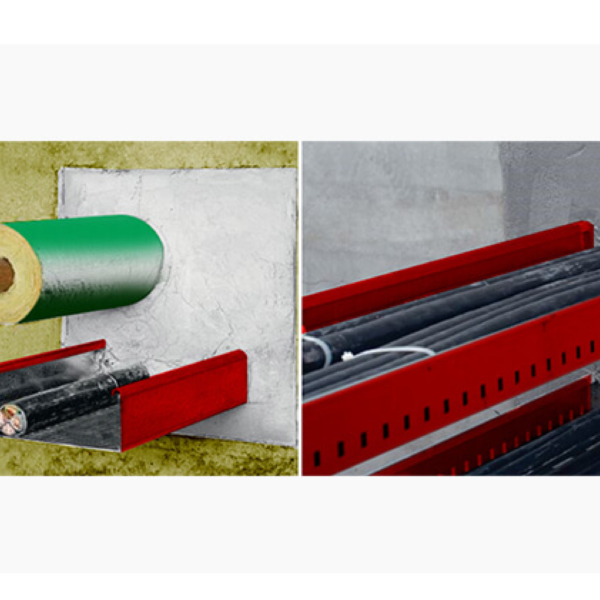

STARBLAZE 32I01 DI-ELECTRIC FLOOR COATING-A

A self–leveling solvent free, high breakdown voltage, protection & insulation coating, developed from a unique cycloaliphatic amine curative, designed to provide insulation safety flooring.

- High dielectric strength & insulation resistance.

- High build –up possibility.

- High Adhesion properly.

- Very good Chemical resistance.

- Self-Leveling.

GM5-9

Submersible drainage pump

- Submersible drainage pump constructed with composite polymers developed especially for this product.

- Double shaft seal with oil chamber.

- Small dimensions and great performance, for use in a wide variety of applications, for flow rates up to 217 litres per minute.

- With float switch for automatic start and stop.

GM 10-8

Submersible drainage pump

- Submersible drainage pump constructed with composite polymers developed especially for this product.

- Double shaft seal with oil chamber.

- Small dimensions and great performance, for use in a wide variety of applications, for flow rates up to 233 litres per minute.

- With float switch for automatic start and stop.

GX ZERO

Submersible clean water pumps

- Single-impeller submersible pumps in chrome-nickel stainless steel, with vertical delivery port and suction non-return valve.

- Suction capability up to 1 mm from the bottom. Motor cooled by the pumped water passing between the motor jacket and the external jacket.

- Double shaft seal with oil chamber.

- The pump is fitted with a suction non-return valve which, during operation, allows to manually move the pump to several points in the room and draw water up to 1 mm avoiding that the pump loses its priming.

GXR, GXV

Stainless steel submersible pumps

- Single-impeller submersible pumps in chrome-nickel stainless steel, with vertical delivery port.

- GXR: with open impeller.

- GXV: with free-flow (vortex) impeller.

- Motor cooled by the pumped water passing between the motor jacket and the external jacket.

- Double shaft seal with oil chamber.

GQR

Submersible drainage pumps.

- Single-impeller submersible drainage pump, with open impeller.

- GQR: with vertical threaded delivery port (G 1 1/2).

- GQR 10 32: with horizontal flanged and threaded delivery port (DN 32, PN 6 – G 1 1/2).

- Double mechanical shaft seal with interposed oil chamber, to protect against dry-running.

GQV, GQS

Submersible sewage and drainage pumps.

- Single-impeller submersible pumps, with free-flow (vortex) impeller.

- GQS: with vertical threaded delivery port G 1 1/2″ or G 2″.

- GQV: with horizontal G 2” or G 2”1/2 threaded delivery port and with DN 50 or DN 65 flanged delivery port.

- Double mechanical shaft seal with interposed oil chamber, to protect against dry-running.